Understanding Magnetic Reed Switch Construction: An Overview of the Three Main Types

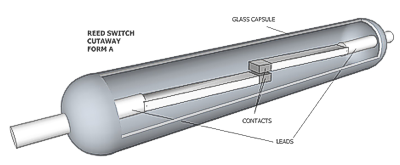

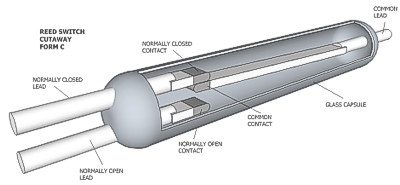

Typical magnetic reed switch construction can be broken down into three main types. Depending upon type, the magnetic reed switch can be constructed of either two or three leads, each having thin reed-like contacts attached. Both the contacts and a portion of the leads are housed within a tubular shaped, hermetically sealed (airtight) glass capsule.

Typical magnetic reed switch construction can be broken down into three main types. Depending upon type, the magnetic reed switch can be constructed of either two or three leads, each having thin reed-like contacts attached. Both the contacts and a portion of the leads are housed within a tubular shaped, hermetically sealed (airtight) glass capsule.

In a Single Pull-Single Throw configuration (Form A and Form B) magnetic reed switch, one lead exits each end of the hermetically sealed, tubular-shaped glass capsule, In a Single Pull-Double Throw magnetic reed switch configuration (Form C), one lead exits one end of the glass capsule, while two leads exit the other end. These leads are comprised of a low magnetic reluctance material, such as annealed iron.

Much like electricity, magnetic energy (magnetic flux) will follow a path of least resistance. Therefore, low reluctance materials provide a needed low-resistance path for magnetic flux. Low-reluctance materials themselves are generally excellent conductors of magnetic flux, though are poor at retaining magnetic energy. This is also what prevents a magnetic reed switch from becoming demagnetized over time.

Much like electricity, magnetic energy (magnetic flux) will follow a path of least resistance. Therefore, low reluctance materials provide a needed low-resistance path for magnetic flux. Low-reluctance materials themselves are generally excellent conductors of magnetic flux, though are poor at retaining magnetic energy. This is also what prevents a magnetic reed switch from becoming demagnetized over time.

Each lead of a magnetic reed switch contains a small area which overlaps the other lead. These areas of overlap are the reed switch contacts, or the physical point at which the leads touch. The contact areas are typically plated with a ferromagnetic material, such as Rhodium or Ruthenium. This plating, when applied to the low reluctance metal of the lead, forms an area for magnetic energy to temporarily collect in sufficient strength as to cause the contact to change position, and thereby changing the state of the magnetic reed switch. This plating also helps to retain the longevity of the leads, thereby enabling literally millions of successful magnetic reed switch activations without wear.

hermetically sealed environment

The glass capsule that is molded and hermetically sealed around the leads of the magnetic reed switch provides the switch’s physical structure. During the capsule molding process, the atmosphere inside of the glass capsule is replaced with an inert gas or a vacuum. Both inert gases and vacuum are said to be high reluctance, meaning that this type of environment aids in focusing the magnetic energy toward the low reluctance of the leads and contacts. In addition, the hermetically sealed environment of the glass capsule protects the contacts from damage or obstruction by minute particles of debris or moisture.