About Reed Switch Developments Corp: What is a Reed Switch?

We invite you to learn more about Reed Switch Developments Corp. and our core product offering, a magnetic based reed switch sensor. We’ll begin with answering a very common question, “What is a reed switch?”

What is a Magnetic Reed Switch?

A magnetic reed switch is, simply put, a type of electrical switch, or sensor.

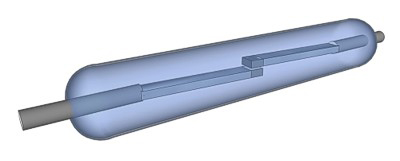

The term “Magnetic Reed Switch” can refer to either the small glass electronic component, as shown in the above drawing, or a complete assembly that is based around this, or a similar type, of electronic component. On this page, “magnetic reed switch” will be used to refer to the component itself and its overall functionality. But generally, what is true for a reed switch component is also true for a complete assembly. Magnetic reed switches are often also otherwise referred to as magnetic switches, magnetic sensors, proximity switches or proximity sensors.

As the name implies, a magnetic reed switch operates by magnetic field.

Like any other type of electrical switch, a magnetic reed switch is used to control the flow of electricity. If the contact of a magnetic reed switch is open, electricity cannot flow. If the magnetic reed switch is closed, electricity can flow. Unlike most other types of mechanical switches, however, magnetic reed switches themselves do not require someone, or something, including but not limited to external power sources, to physically operate them.

The magnetic reed sensors, switches and actuator products offered by Reed Switch Developments Corp. are designed to operate by the proximity of a magnetic field. In order to change the state of a magnetic reed switch from open to closed, or vice versa, as to allow the flow of electricity, a source of magnetic energy merely needs to pass just near enough to the magnetic reed switch in order to cause the required level of actuation. The source of the magnetic energy, or the actuator, is usually just a simple magnet that is designed to be seamlessly paired with the switch, or sensor.

A magnetic reed switch is inherently immune to mechanical wear.

A unique characteristic of magnetic reed sensors, or switches, is their capability to support high-speed switching applications without mechanical wear. This means that they provide long, trouble-free service life over many thousands of cycles, with extreme reliability –all provided that they are used within published specifications, and that the customer has selected the “best fit” magnetic reed switch based sensing solution for their own unique application requirements.

This longevity and reliability, of course, makes the magnetic reed switch an exceptionally cost-effective solution. In addition, magnetic reed sensors are versatile, easy to install, compact and lightweight, and require no external supply voltage for operation.

Magnetic reed switches may be actuated through non-ferrous materials.

Magnetic reed switches, or magnetic reed sensors, can also be actuated through non-ferrous (non-magnetic) materials, including wood, aluminum, plastic, or stainless steel, so long as the magnetic field of the chosen actuator is strong enough to reach the switch through the thickness of the material. What this means is that a magnetic reed switch may be kept enclosed, or hidden, within a sealed environment.

The magnetic reed switch, or magnetic reed sensor, may therefore be externally actuated without compromising the effectiveness of the switch, other protected components, or any other materials that are otherwise located inside of the enclosure.

Magnetic reed switches may be used with ferrous metals.

While generally not recommended, magnetic reed switches may also be used with ferrous (magnetic) materials, such as steel and iron, in certain circumstances. Within those applications, however, special considerations must be made as to determine precisely how the magnetic field of the reed switch actuator will be affected by the external magnetic properties of any surrounding materials. It is therefore recommended that customer prototype sample testing of the chosen magnetic reed switch, or magnetic reed sensor model, is fully conducted in advance of any final installation.

Reed Switch Developments Corp. generally recommends that all customers consider performing pre-installation prototype testing, as industry best practice. This helps to ensure the continuous and consistent operation of a selected magnetic reed switch, or magnetic reed sensor, and especially so within applications involving such ferrous materials.

The prototype testing helps to confirm that a “best fit” magnetic reed switch sensor has been selected for the application. It also helps to confirm the optimal placement of both the magnetic reed switch and actuator within the intended installation environment.

By implementing such pre-testing protocols, an end-user is able to ensure that the operation of the chosen magnetic reed switch, or magnetic reed sensor, is successful in the presence of such ferrous materials, as well as confirming that the switch’s magnetic field will not be otherwise absorbed or distorted upon installation.